|

||||||||

|

|

|

|

||

|

|

* Application

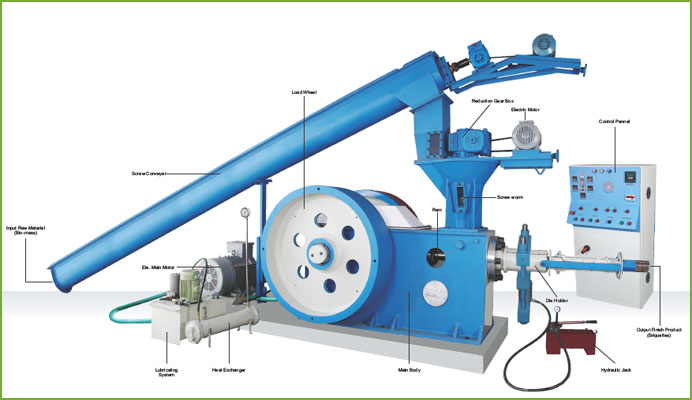

Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes

(Bio-coal). * Description of Briquetting Plant ( Super -60)

The Briquetting Plant is a ram type press designed for continuous heavy-duty operation

with two load wheels. One of the load wheels acts as a pulley, and driven by the

main motor through a flat belt. Forced lubrication is provided by oil lubrication

system which gives a longer life to the bushes.

Dry agro - forestry waste as a raw material is fed through the screw conveyor to

Kupy by means of vertical screws, with its own-geared motor. It pre-compress and

forces the material downward into the feeder box. From the feeder box the material

is forced by the Ram through Taper die and due to high pressure & heat, raw material

(Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes

come out from die holder and passes through natural cooling lines.

During Process lignin content in the raw material (Biomass) is transformed into

liquid form & acts as a natural binder. Therefore it is called the Binder less Technology. Super-60 Model is ideal for low production and best for waste management in agro and wood industries. If raw material ( Biomass) is available in powdery form, so this smaller model is suitable to convert Briquettes. * Biomass Briquetting Plant Super -60

* Production Capacity of Biomass Briquetting plant ( Super- 60)

* Raw material ( Biomass) Specifications

* Output Briquettes (Bio-coal) Specification

* Production Capacity Output capacity is depends on the bulk density of Raw Material. So it will vary with different input raw material.It will be 400 Kg to 600 Kg/Hr. If the raw material is not in powdery form then Hammer Mill is required additionally

* Silent Futures of Radhe Engineering Co. - Biomass briquetting Plant (Super-60)

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||