|

||||||||

|

|

|

|

||

|

|

* Application

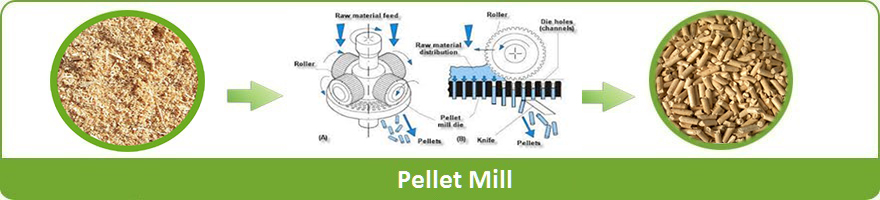

The Pellet Mill is for converting powdery form biomass or sawdust to 8mm plus diameter

and small pieces of pellets

Pellets are ideal fuel for fluidized bed thermal application. Also used in Bio-stove

and Pellet Burner.

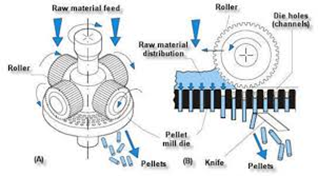

* System Description of Pellet Mill

Pelletizing is a binder less process to compact finely pulverized material into

firm mass of a required shape and size by extruding it through a metallic ring die

or Flat Die. Instead of Binder steam works as a natural binder for pelletizing.

Finely ground material is fed into the Pellet Mill through a feeder and then pressed

into a rotating ring die with the help of two press rolls free to rotate on their

respective shafts. The resulting pressure compresses the material and extrudes it

through the holes in the die

In flat die Pellet Mill same two or four press roller rotate and dandified material

as required hole size. For smaller model flat die is good. * Screw Briquetting

* Production Capacity of Pellet Mill

* Raw material ( Biomass) Specifications

* Output Pellet Specification

* Silent Futures of Radhe Engineering Co. - Pellet Mill ( Ring Die / Flat Die)

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||